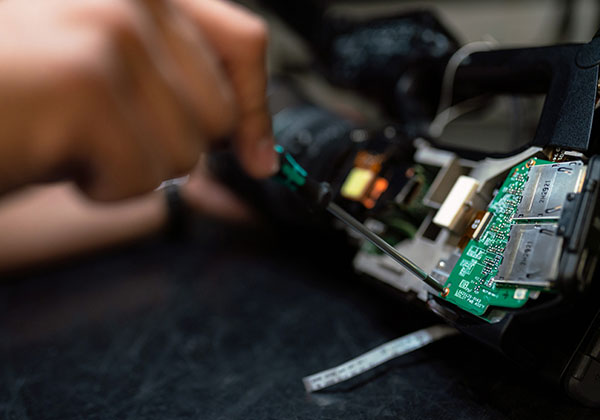

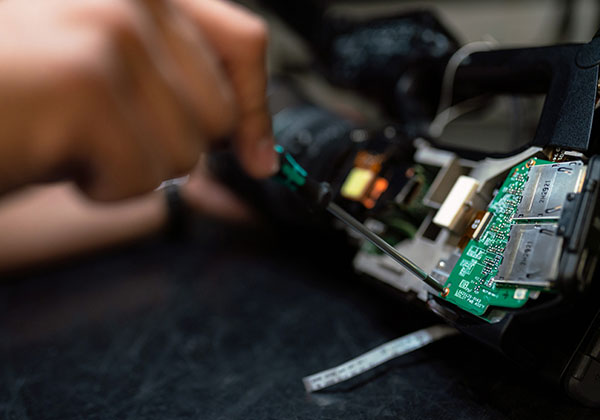

Hardware

Laser cutting uses a high power density laser beam to irradiate the material to be cut, so that the material is quickly heated to the vaporization temperature and evaporated to form holes. As the beam moves to the material, the holes continuously form a narrow width (such as about 0.1mm). Cut seams to complete the cutting of materials; mechatronics cutting machines are called CNC cutting machines, such as CNC plasma, flame cutting machines (CNC Cutting Machine), CNC cutting machines, which are driven by digital programs. When moving on the machine tool, the randomly equipped cutting tool cuts the object. The CNC suspension tapping machine adopts rocker arm bracket and servo motor, which has high tapping efficiency, flexible operation, and can be moved at will. It is suitable for all machinery manufacturing industries, such as machine tools, mold (factory) machinery, plastic machinery, printing machinery, and packaging machinery manufacturing. Factory, construction machinery, automobile and motorcycle parts, aero-engines, rolling stock, tobacco machinery and general machinery and other industries, Hengliighting lighting project uses all kinds of advanced equipment, which can realize all kinds of pipe hardware processing.

More >